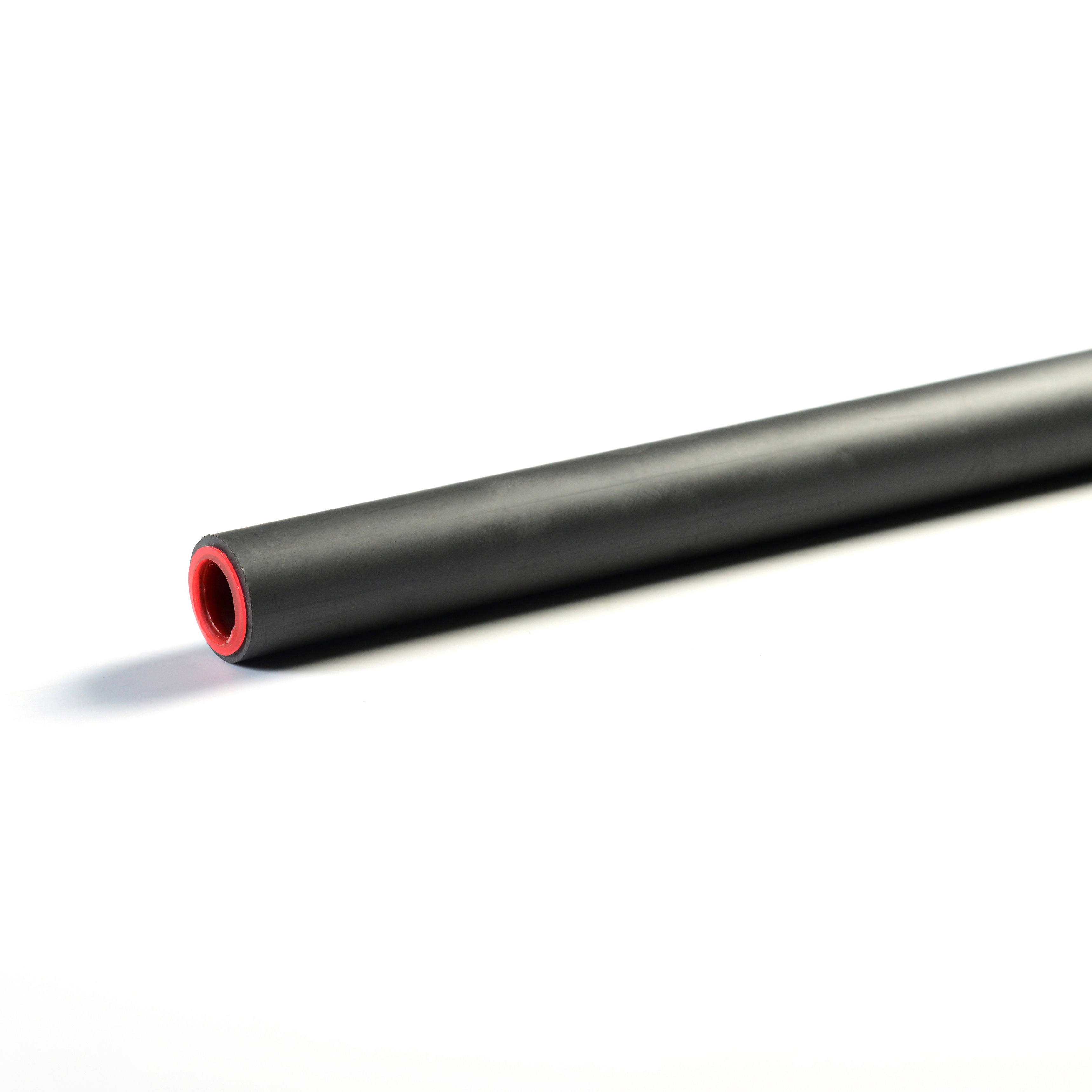

Fosfat sax ahedtuubowaa nooc cusub oo tuubooyin u adkaysta xidhashada, kaas oo adeegsada farsamada buul-galka ah ee isku-dhafka ah.Waxaa la sameeyay by shaqada farsamo ee miiqan buul ka kooban laba walxood oo biraha ceeriin oo kala duwan si wadajir ah, si cilmiyeysan ka faa'iidaysiga dhumucdiisuna waxay tahay derbiga saldhigga dibadda si ay u qaadaan cadaadiska shaqada ee nidaamka dhuumaha, iyo iyadoo la isticmaalayo biibiile daxalka u adkaysta tuubada si ay u qaadaan shuruudaha daxalka ee nidaamka dhuumaha.

Marka la barbar dhigo birta daabka daawaha u adkaysta xidhashada dhaqameed, birta kabka birta dabaysha ee xidhan, birta dhoobada isku dhafan, iyo tuubada dhagaxa tuuray, fosfat-saxahaned tuubada waxay leedahay faa'iidooyinka soo socda.

1. caabbinta xidhashada wanaagsan.

2. Cadaadiska cadaadiska sarreeya, oo ku habboon heerarka cadaadiska sare.

3. Dahaarka gudaha ayaa si adag loogu daraa tuubada birta ee dibadda, iyo hab gaar ah ayaa loo doortaa si loo sameeyo isku-dhafka fiyuuska ee u dhexeeya lakabyada isku-dhafka ah, hubinta isku-kalsoonaanta shaqada.

4. Waxay leedahay iska caabin wanaagsan oo shoogga farsamada ah iyo shoogga kulaylka.

5. Isku xirka qalabka ku habboon.Flanges iyo kala-goysyada dabacsan ayaa loo isticmaali karaa isku xirka, waana la jari karaa ama la alxan karaa marka la doono.

Baaxadda isticmaalka:

Nidaamka gudbinta budada dhuxusha, tuubada gudbinta dambaska qalalan ee qoyan, iyo nidaamka dhuxusha dhagaxa ee dhirta tamarta kulaylka

Nidaamyada kale ee gudbinta pneumatic ee walxaha budada ah

Nidaamka gaadiidka hydraulic slag iyo gaadiidka slurry oo leh cabbir weyn

Gaadiidka agabka macdanta kala duwan

1. Saamaynta Phosphating

(1) Saamaynta fosfatinta ka hor dahaadhka

① Kordhi xabagta u dhaxaysa lakabka daahan (sida daahan rinjiga) iyo workpiece.

② Hagaajinta iska caabinta daxalka ee daahan dusha sare ee workpiece ka dib daahan.

③ Hagaajinta qurxinta.

(2) Saamaynta fosfitinta aan daahan

① Hagaajinta caabbinta xirashada ee qalabka shaqada.

② Hubi jilicsanaanta qalabka shaqada inta lagu jiro mashiinka.

③ Hagaajinta iska caabinta daxalka ee qalabka shaqada.

2. Codsiga fosfatinta

Fosfaatka birta ah waxaa inta badan loo isticmaalaa ilaalinta daxalka iyo sida filim salka u ah rinjiga.

(1) Filimka fosfatka ee ilaalinta daxalka

① Filimka fosfatka ee ilaalinta ayaa loo isticmaalaa daaweynta ilaalinta daxalka ee qaybaha birta.Nooca filimka fosfitinta wuxuu noqon karaa zinc ama manganese.Baaxadda unug kasta ee xuubka waa 10-40 g/m2.Marso saliid ka hortagta miridhku, dufan, wax, iwm. fosfooraska ka dib.

② Filim fosfating ah oo loogu talagalay substrate rinjiga

Kordhi xabagta iyo ilaalinta u dhaxaysa filimka rinjiga iyo birta birta ah ee shaqada.Nooca filimka fosfitinta wuxuu noqon karaa zinc ku salaysan ama zinc calcium ku salaysan.Baaxadda aagga halbeegga filimka fosfatinta waa 0.2-1.0 g / m2 (oo loo isticmaalo lakabka hoose ee rinjiga qaybaha birta ee waaweyn);1-5 g / m2 (oo loo isticmaalo lakabka hoose ee rinjiga qaybaha birta guud);5-10 g/m2 (lakabka saldhigga rinjiga ee qaybaha birta ee aan qalloocin).

(2) Dahaarka fosfate-ka ee loogu talagalay habsami u shaqaynta qabow

Miisaanka filimka halkii cutub ee fiilada birta ah iyo sawirka tuubada birta ee welded waa 1-10 g / m2;Miisaanka filimka halkii cutub ee sawirka tuubada phosphating saxda ah waa 4-10 g/m2;Miisaanka filimka halbeeg kasta oo ka sameysan qaybo bir ah oo qabow ayaa ka weyn 10 g/m2.

(3) Dahaarka fosfate-ka si loo yareeyo khilaafyada

Filimka fosfatinta ayaa yarayn kara khilaaf.Guud ahaan, fosfatinta manganese ku salaysan ayaa la isticmaalaa, fosfatinta ku salaysan zinc sidoo kale waa la isticmaali karaa.Qalabka shaqada ee leh nusqaamo yaryar oo firfircoon, xajmiga filimka fosfatinta waa 1-3 g / m2;Qaybaha shaqada ee leh nusqaano taam ah oo firfircoon (gearbox gears), tirada filimka phosphating waa 5-20 g/m2.

(4) Dahaarka Fosfat ee dahaarka korantada

Guud ahaan, fosfooraska ku salaysan zinc ayaa la isticmaalaa.Loo isticmaalo daawaynta wafer fosfatka silikoon ee matoorada iyo transformers.

Waqtiga boostada: Agoosto-24-2023