ST37 ST35 ST52 tube bir saxan sare

Din 2391 tuubo bir ah oo aan xad lahayn

Tilmaamid

| Heerka | DIN2391 DIN1630 DIN2448 |

| Darajo | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Xaaladda gaarsiinta | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Cabbirka | OD: 4 ilaa 219mm dhumucda 0.5-35mm, Dhererka: 3m,5.8,6 ama sida waafaqsan shuruudaha |

| dhame | Dusha galvanized (Sliver/Jaalle/ Midab leh) Daahan Zinc oo ah 8-12um |

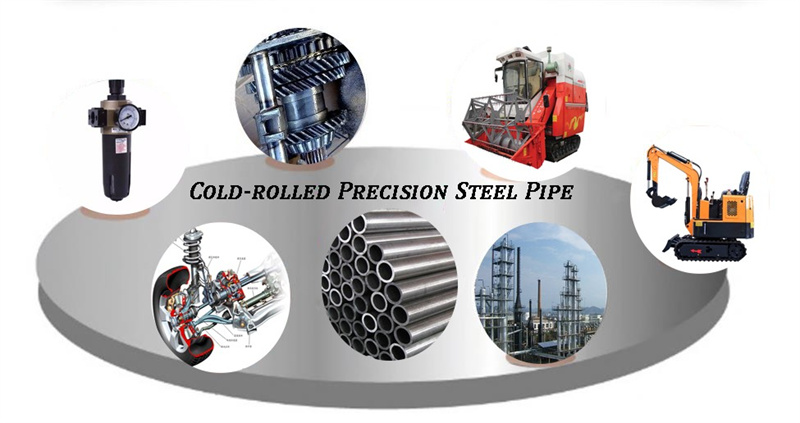

| Codsiga | Nidaamka Haydarooliga;Baabuur/bas;gaadiidka dhismaha |

| Waqtiga dirida | A.3 maalmood haddii ay tani tahay alaab kayd ah. B. Qiyaastii 30 maalmood iyadoo loo eegayo tirada |

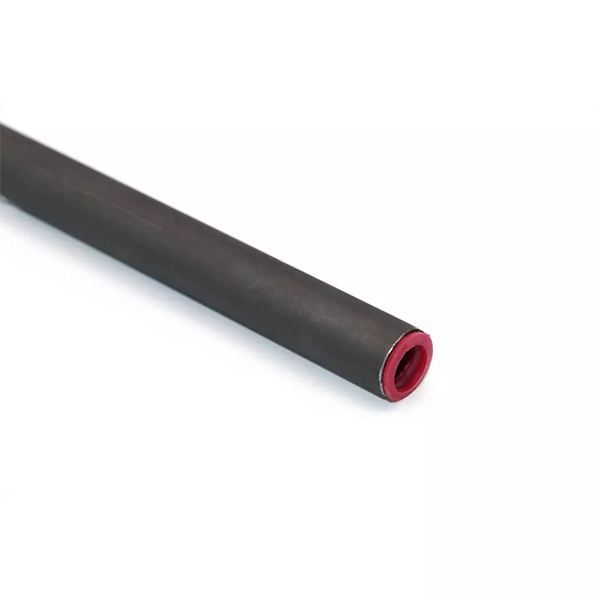

DAAWAYNTA SORKA

1. Tube Bare (Lacag la'aan): dhalaalaya oo siman

A. Silver galvanized

B. Jaalle galvanized

C. cagaar saytuun oo dahaarsan

Dhumucda lakabka: 8-20um, Tijaabada buufinta cusbada: 48-150 saacadood

3. Fosfooraska madow

Goobaha kala duwan

1. Garoomada baabuurta

A. Khadadka duritaanka shidaalka

B. CNG (gaaska dabiiciga ah ee ciriiriga ah) tube-- Cadaadiska dilaaca: 1307Bar, Cadaadiska Shaqada: agagaarka 350bar

C. Gudbinta wadista: curiyayaasha tiirarka hagida

D. Gear shafts, bireega gacanta, faashashka hore, barkinta hawada neefta lagu nuugo, xasiliyayaal, xidhayaasha fadhiga, ulaha hore-wheel wadista

2. Goobaha Haydarooliga

A. Wareegyada Haydarooliga (HPL), xadhkaha pneumatic, iyo hakinta hadhidarooliga

B. Dhululubada Haydarooliga (HPZ)

Halabuurka Kiimikada

| Heerka Birta | C | Si | Mn | P | S | Al | |

| Magaca | Maya | max | max | max | max | max | max |

| ST35 | 1.0308 | 0.17 | 0.35 | 0.4 (daqiiqo) | 0.025 | 0.025 | - |

| ST45 | 1.0408 | 0.21 | 0.35 | 0.4 (daqiiqo) | 0.025 | 0.025 | - |

| ST52 | 1.058 | 0.22 | 0.55 | 1.6 | 0.025 | 0.025 | - |

Guryaha Makaanikada

| Heerka Birta | Xoogga Wax-soosaarka (Mpa) | Xoogga Jilitaanka (Mpa) | Kordhinta (%) | |

| Magaca | Maya | ReH (min) | Rm(min) | A(daqiiqo) |

| ST35 | 1.0308 | 235 | 340 ilaa 480 | 25 |

| ST45 | 1.0408 | 255 | 440 ilaa 570 | 21 |

| ST52 | 1.058 | 355 | 490 ilaa 630 | 22 |

Dulqaad

| OD | Dulqaadka la oggol yahay | Dulqaad gaar ah | ||

|

| GB/T3639 | DIN2391 | OD | WT |

| 4mm-20mm | ±0.10mm | ±0.08mm | ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.10mm | ±0.08mm | ±0.08mm | ±0.08mm |

| 31mm-40mm | ±0.15mm | ±0.15mm | ±0.10mm | ±0.08mm |

| 41mm-60mm | ±0.20mm | ±0.20mm | ±0.15mm | ±0.15mm |

| 61mm-80mm | ±0.30mm | ±0.30mm | ±0.20mm | ±0.20mm |

| 81mm-120mm | ±0.45mm | ±0.45mm | ±0.30mm | ±0.30mm |

Xaaladda gaarsiinta

| Magacaabidda | Astaanta | Sharaxaada |

| Qabow dhammaatay (adag) | BK(+C) | Tuubooyinka laguma daawayn kulaylka ka dib samaynta qabowga ugu dambeeya, sidaas darteed, waxay leeyihiin iska caabin sare oo u ah qallafsanaanta |

| Qabow dhameeyay (Jilicsan) | BKW | Daawaynta kulaylka ugu dambeysa waxaa ku xiga sawir qabow oo ku lug leh qallafsanaan xaddidan.Ka-hortagga ku habboon ee dheeraadka ah waxay oggolaataa heer gaar ah oo qabow samaynta (tusaale foorarsi, ballaarin) |

| (+LC) | ||

| Qabow dhammeeyey oo werwerka laga dejiyey | BKS(+SR) | Daawaynta kulaylka ayaa la mariyaa iyadoo la raacayo habraaca samaynta hargabka ee u dambeeyay.Iyadoo la raacayo shuruudaha habaynta ku habboon, kororka culaysyada haraaga ah ee ku lug leh ayaa awood u siinaya samaynta iyo farsamaynta labadaba ilaa heer go'an. |

| La xiray | GBK(+A) | Habka ugu dambeeya ee samaynta Qabow waxa ku xiga ka-noqoshada jawiga la xakameeyey. |

| Caadiyan | NBK(+N) | Habka ugu dambeeya ee samaynta qabowga waxaa ku xiga ka-goynta ka sarreysa barta isbeddelka sare ee jawiga kontoroolka ah. |

Xaqiijinta Tayada

1. Ku adag sida uu qabo DIN2391/EN10305 ama heer kale.

2. Muunad: Muunaduhu waa u bilaash baaritaanka.

3. Tijaabooyinka: Tijaabada buufinta milixdu / Tijaabada xajinta / Eddy hadda / tijaabinta ka kooban kiimikaad sida waafaqsan codsiga macaamiisha

4.Certificate: IATF16949, ISO9001, SGS iwm.

5.EN 10204 3.1 Shahaadada

Baakadaha alaabta