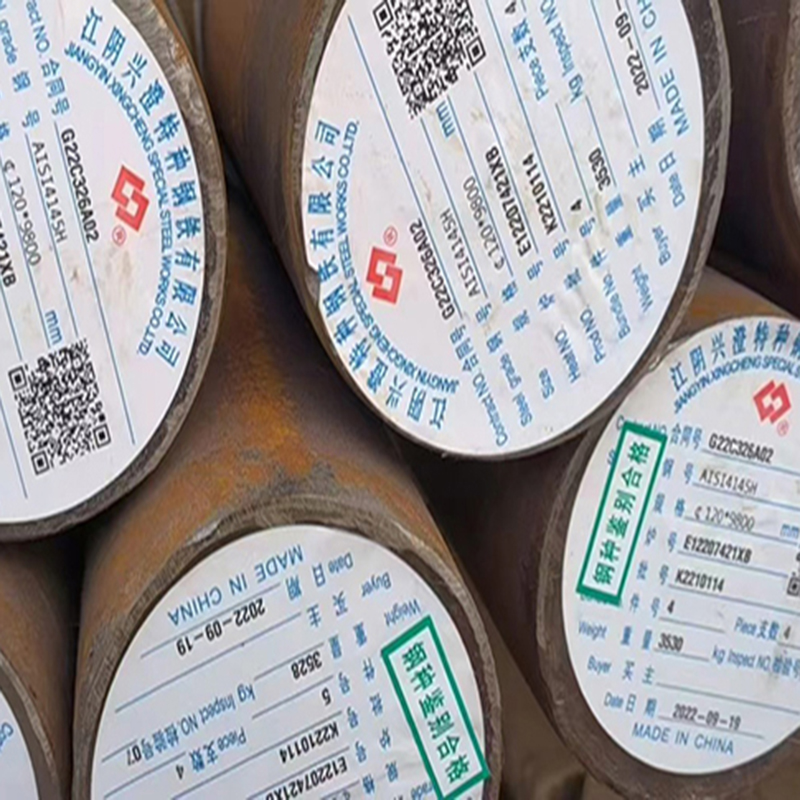

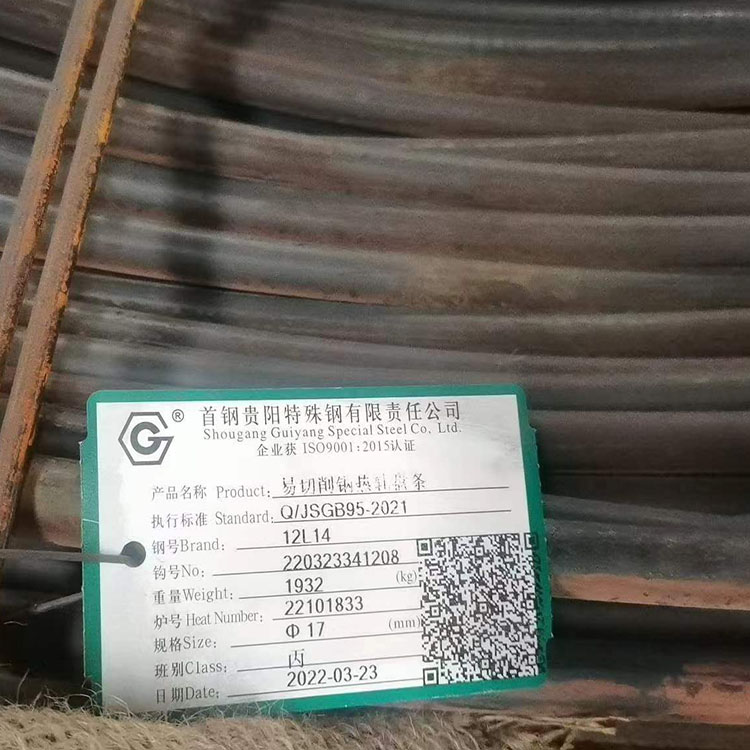

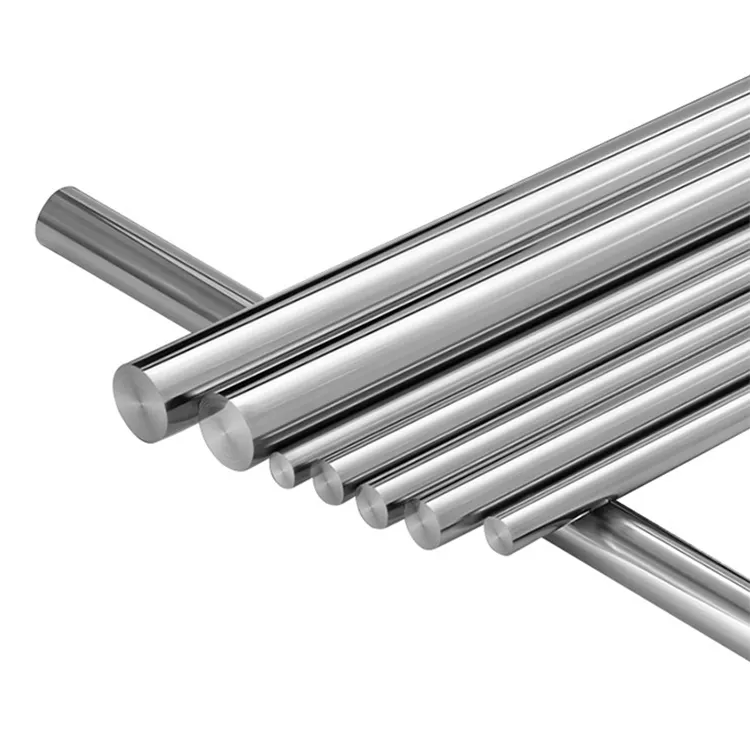

SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar

Waxaan raacnaa mabda'a maamulka ee "Quality is exceptional, Assistance is supreme, Reputation is first", and will sincerely create and share success with all clients for SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar, Waxaan sidoo kale si joogto ah u ugaarsanaynaa in la dhiso xiriir la alaab-qeybiyeyaal cusub si ay u siiyaan horumar iyo wax-ka-beddel kale oo caqli-gal ah oo ka beddelan dukaammadayada qiimaha leh.

Waxaan raacnaa mabda'a maamulka ee "Tayadu waa mid gaar ah, Caawimada ayaa ugu sareysa, Sumcada ayaa ugu horeysa", waxaana si daacad ah u abuuri doonaa oo aan la wadaagi doonaa guusha dhammaan macaamiisha4130 Birta Birta, Waxaan rajeyneynaa inaan sameyn karno wadashaqeyn waqti dheer ah dhammaan macaamiisha.Waxaan rajeyneynaa inaan horumarin karno tartanka oo aan gaarno xaaladda guul-guuleysiga annaga iyo macaamiisha.Waxaan si daacad ah u soo dhaweyneynaa macaamiisha ka kala yimid adduunka oo dhan inay nala soo xiriiraan wax kasta oo aad u baahan tahay!

Astaamaha

4130 4135 4140 4145H birta birta ah waa bir daawaha carbon hooseeya.Waxay ka tirsan yihiin Chrome-Molly alloy oo ka kooban chromium iyo molybdenum oo ah wakiilada xoojinta.

4130 bir wareeg ah ayaa leh karti shaqo oo wanaagsan, habacsanaan wax-qabad yar, iyo iska caabin daal aad u fiican.Waxay ka tirsan tahay qaybta birta adag ee dhexdhexaadka ah ilaa sare.Daawaynta kulaylka ka dib, 4140 waxay leedahay awood wanaagsan iyo sifooyin farsamo oo dhamaystiran, karti hab-socod wanaagsan, iyo waxsoosaar sare.Heerkulka adeeggu waa 427 darajo Celsius.

4140 waxa uu leeyahay xoog sare, karti adag, adayg, iyo qallafsanaan inta lagu jiro deminta.Waxay leedahay xoog gurguurta oo sarreeya iyo xoog adkaysi heerkul sare.Waxaa loo isticmaalaa wax soo saarka foornada oo u baahan xoog sare iyo qaybo ka weyn oo la demiyo iyo kuwa dabci ah oo ka badan 4135 birta, sida qalabka waaweyn ee jiid jiidashada, qalabka gudbinta xoojisa, faashashka danbe, ulo isku xidha iyo clips guga oo aad u raran.

Tilmaamid

| Magaca Alaabta | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Qalab | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Heerka | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ilaa 600mm | |

| Dusha sare | Rinji madow, qaawan, la sifayn, dahaadhay Chrome | |

| Tilmaamaha | Bar wareega | 8mm ~ 800mm |

| Bar xagasha | 3mm * 20mm * 20mm ~ 12mm * 800mm * 800mm | |

| Bar labajibbaaran | 4mm * 4mm ~ 100mm * 100mm | |

| Baar fidsan | 2 * 10mm ~ 100 * 500mm | |

| Laba geesood | 4mm ~ 800mm | |

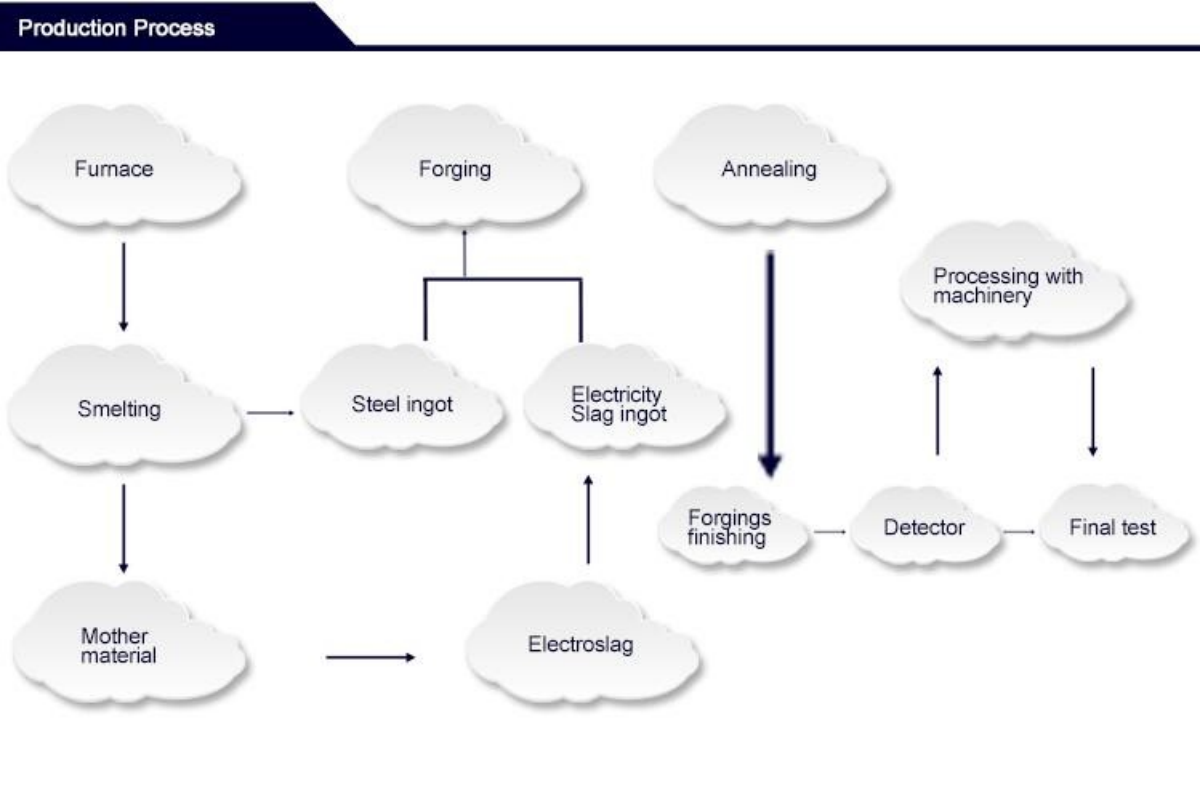

| Habka | Foornada korantada ayaa dhalaalay, la been abuurtay oo la tirtiray, baarka wareegsan ayaa leexday. | |

| Adag: | HBS 217Max (Ka duwan daawaynta kulaylka) | |

| Imtixaanka UT | SEP 1921/84/2 C/c fasalka. | |

| Dulqaad | Dia -0/+ 0 ~ 5mm, Dhumucda -0/+ 0 ~ 5mm, Balladhka: -0/+ 0 ~ 10mm. | |

| Dhererka | 2m,4m,5.8m,6m,11.8m,12m ama sida loo baahdo. | |

| Xidhmada | Xirmooyinka badda mudan. | |

| Halbeeg kala duwan oo siman | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| 4135 | 35Crmo | 1.7220 (34CrMo4) | SCM432 |

| 4145H | - | - | - |

Halabuurka Kiimikada

| Halabuurka Kiimikada (%) | |||||||

| Darajo | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Guryaha Makaanikada

| Astaamaha: |

| 1. Bir daawaynta hoose oo ay ku jiraan molybdenum iyo chromium sida wakiilada xoojinta; |

| 2. Aad uga fiican aragtida weldability fusion; |

| 3.Daawaha waxaa lagu adkeyn karaa daaweynta kulaylka. |

Dulqaad

| Xaaladda gaarsiinta |

| 1.Hot duuban |

| 2.Annealed |

| 3. Caadiyan |

| 4. Demisay oo xanaaqsan |

Xaaladaha daaweynta kulaylka

1.Annealing: 880 ℃ qaboojinta foornada

2. Caadiyan: 880 ~ 870 ℃ Qaboojinta hawada

3. Adag: 820 ~ 870 ℃ Biyaha qaboojinta

4.Tempering: 550 ~ 650 ℃ Qaboojin degdeg ah

Guryaha makaanikada waxaa lagu heli karaa daawaynta kulaylka kala duwan.

Xidhmada

1.By xidhmooyinka, xidhmo kasta oo miisaankeedu ka yar yahay 3 tan, ee dibadda yar

dhexroor wareeg ah, xidhmo kasta oo leh 4 - 8 xariijimo bir ah.

2.20 cagood weel ka kooban cabbir, dherer ka hooseeya 6000mm

3.40 cagood weel ka kooban cabbir, dherer ka hooseeya 12000mm

4.By markabka bulk, khidmadda xamuulku waa ku yar yahay xamuulka badan, iyo weyn

cabbirrada culculus laguma rari karo weelasha waxaa lagu rari karaa xamuul badan

Hubinta tayada

1.Cudud waafaqsan Shuruudaha

2. Tusaale: Muunad ayaa diyaar ah.

3. Tijaabooyinka: Tijaabada buufinta milixdu / Tijaabada xajinta / Eddy hadda / tijaabinta ka kooban kiimikaad sida waafaqsan codsiga macaamiisha

4.Certificate: IATF16949, ISO9001, SGS iwm.

5. EN 10204 3.1 Shahaadada

Birta wareega ee SAE4130 waa birta qiimaha daawaha ah.Heerka ASTMA29/A29M-04.Summada gudaha ee u dhiganta: 30CrMo Summada Jabbaan ee u habboon: SCM430 (SCM2) Summada Jarmalka ee u habboon: 34CrMo4 (1.7220)

4130 birta qaabdhismeedku waxay leedahay awood sare iyo adayg, adkeysi sare, iyo dhexroor adag oo adag oo 15-70mm saliid ah;Awoodda kulaylka ee birta sidoo kale waa wanaagsan tahay, oo leh awood ku filan oo heerkul sare ah oo ka hooseeya 500 ℃, laakiin xooggeedu si weyn ayuu hoos ugu dhacayaa 550 ℃;Marka element Alloy uu ku yaal xadka hoose, alxanka waa mid aad u wanaagsan, laakiin marka ay ku dhowdahay xadka sare, weldability waa dhexdhexaad, iyo preheating ka sarreeya 175 ℃ ayaa loo baahan yahay ka hor alxanka;Birtu waxay leedahay mashiin wanaagsan iyo caag dhexdhexaad ah inta lagu jiro qallafsanaanta qabow;Inta lagu jiro daawaynta kulaylka, waxaa jira xanaaq la mid ah oo jilicsan oo u dhexeeya 300-350 ℃;Waxaa jira u janjeera inay sameeyaan baro cadcad.

SAE4130 waxaa inta badan loo isticmaalaa in warshadaha wax soo saarka mishiinada size dhexdhexaad ah si ay u soo saaraan bakhtiyo iyo qaybo ka kulul oo leh qaybo waaweyn oo iskutallaabta ah oo ka shaqeeya xaaladaha walaaca sare, sida shafts, spindles, iyo giraangiraha xakamaynta load sare, boolal, boolal madax double, marsho, iwm;Loo isticmaalo warshadaha kiimikada si loo soo saaro qaybaha alxanka leh, qaab dhismeedka alxanka ah oo ka kooban taarikada iyo tuubooyinka, iyo marinada cadaadiska sare leh oo leh heerkul aan ka badnayn 250 ℃ oo ku shaqeeya dhexdhexaad ka kooban nitrogen iyo hydrogen;Warshadaha wax soo saarka ee marawaxadaha uumiga iyo kuleyliyeyaasha, waxaa loo isticmaalaa in lagu soo saaro xirmooyinka shaqada ee ka hooseeya 450 ℃, flanges iyo flanges daboolaya cadaadis sare oo ka hooseeya 500 ℃.