Tuubada Birta ee Qaybaha Baabuurka / SCM420H SCM440H SCM435

Astaamaha

Heerka Alaabta:

STKM 11A 12A 12B 12C 13A 13B 13C 14A 14B 14C 15A 15C iwm.

Daaweynta Dusha sare:

1.Bareed

2.Madoow oo rinjiyeeyay (daahan varnish ah)

3.Galvanized

4. Saliid

5.Sida ay macaamiishu sheegeen.

JIS G3445 Tuubooyinka birta ee saxda ah ayaa inta badan loo adeegsadaa baabuurta iyo qaybaha mishiinada saxda ah ee baabuurta iyo dhululubada.isticmaalka cadaadiska, iyo sidoo kale qaadista uumiga, biyaha, khadadka gaaska.

Halabuurka kiimikada

| Darajo | Magacaabidda | Unug (%) | ||||||

| C | Si | Mn | P | S | Nb ama V | |||

| Fasalka 11 | A | STKM 11A | 0.12 max. | 0.35 max. | 0.60 max | 0.040 max. | 0.040 max. | - |

| Fasalka 12 | A | STKM 12A | 0.20 max | 0.35 max. | 0.6 max | 0.04 max. | 0.04 max. | |

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Fasalka 13 | A | STKM 13A | 0.25 max. | 0.35 max. | 0.30 ~ 0.90 | 0.040 max. | 0.040 max. | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Fasalka 14 | A | STKM 14A | 0.30 max | 0.35 max. | 0.30 ~ 1.00 | 0.040 max. | 0.040 max. | - |

| B | STKM 14B | |||||||

| C | STKM 14C | |||||||

| Fasalka 15 | A | STKM 15A | 0.25 ~ 0.35 | 0.35 max. | 0.30 ~ 1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 15C | |||||||

| Fasalka 16 | A | STKM 16A | 0.35 ~ 0.45 | 0.40 max. | 0.40 ~ 1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 16C | |||||||

| Fasalka 17 | A | STKM 17A | 0.45 ~ 0.55 | 0.40 max. | 0.40 ~ 1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 17C | |||||||

| Fasalka 18 | A | STKM 18A | 0.18 max. | 0.55 max. | 1.50 max | 0.040 max. | 0.040 max. | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Fasalka 19 | A | STKM 19A | 0.25 max. | 0.55 max. | 1.50 max | 0.040 max. | 0.040 max. | - |

| C | STKM 19C | |||||||

| Fasalka 20 | A | STKM 20A | 0.25 max. | 0.55 max. | 1.60 max. | 0.040 max. | 0.040 max. | 0.15 max |

Guryaha makaanikada

| Heerka Birta | Xoogga Wax-soosaarka (Mpa) | Xoogga Jilitaanka (Mpa) | Kordhinta (%) | |

| Magaca | Maya | ReH (min) | Rm(min) | A(daqiiqo) |

| STKM 11A |

| _ | 290 | 35 |

| STKM 12A |

| 175 | 340 | 35 |

| STKM 12B |

| 275 | 390 | 25 |

| STKM 12C |

| 355 | 4700 | 20 |

| STKM13A |

| 215 | 370 | 30 |

| STKM 11B |

| 305 | 440 | 20 |

| STKM11C |

| 380 | 510 | 15 |

Dulqaad

| QAYBKA | Dulqaadka la oggol yahay | Dulqaad gaar ah | ||

| OD | WT | OD | WT | |

| 4mm-20mm | ±0.25mm | <3mm± 0.3mm;

≥3mm ± 10%

| ±0.05mm | ±0.05mm |

| 20mm-30mm | ±0.25mm | ±0.08mm | ±0.08mm | |

| 31mm-40mm | ±0.25mm | ±0.10mm | ±0.08mm | |

| 41mm-49mm | ±0.25mm | ±0.15mm | ±0.15mm | |

| 50mm-80mm | ± 0.5% | ±0.20mm | ±0.20mm | |

| 81mm-120mm | ± 0.5% | ±0.30mm | ±0.30mm | |

Xaaladda gaarsiinta

| Magacaabidda | Astaanta | Sharaxaada |

| Qabow dhammaatay (adag) | BK(+C) | Tuubooyinka laguma daawayn kulaylka ka dib samaynta qabowga ugu dambeeya, sidaas darteed, waxay leeyihiin iska caabin sare oo u ah qallafsanaanta |

| Qabow dhameeyay (Jilicsan) | BKW | Daawaynta kulaylka ugu dambeysa waxaa ku xiga sawir qabow oo ku lug leh qallafsanaan xaddidan.Ka-hortagga ku habboon ee dheeraadka ah wuxuu ogolaanayaa heer gaar ah oo qabow samaynta (tusaale foorarsi, ballaarin) |

| (+LC) | ||

| Qabow dhammeeyey oo werwerka laga dejiyey | BKS(+SR) | Daawaynta kulaylka ayaa la mariyaa iyadoo la raacayo habraaca samaynta hargabka ee u dambeeyay.Iyadoo la raacayo shuruudaha habaynta ku habboon, kororka culaysyada haraaga ah ee ku lug leh ayaa awood u siinaya samaynta iyo farsamaynta labadaba ilaa heer go'an. |

| La xiray | GBK(+A) | Habka ugu dambeeya ee samaynta Qabow waxa ku xiga ka-noqoshada jawiga la xakameeyey. |

| Caadiyan | NBK(+N) | Habka ugu dambeeya ee samaynta qabowga waxaa ku xiga ka-goynta ka sarreysa barta isbeddelka sare ee jawiga kontoroolka ah. |

Xaaladda gaarsiinta

| Magacaabidda | Astaanta | Sharaxaada |

| Qabow dhammaatay (adag) | BK(+C) | Tuubooyinka laguma daawayn kulaylka ka dib samaynta qabowga ugu dambeeya, sidaas darteed, waxay leeyihiin iska caabin sare oo u ah qallafsanaanta |

| Qabow dhameeyay (Jilicsan) | BKW | Daawaynta kulaylka ugu dambeysa waxaa ku xiga sawir qabow oo ku lug leh qallafsanaan xaddidan.Ka-hortagga ku habboon ee dheeraadka ah wuxuu ogolaanayaa heer gaar ah oo qabow samaynta (tusaale foorarsi, ballaarin) |

| (+LC) | ||

| Qabow dhammeeyey oo werwerka laga dejiyey | BKS(+SR) | Daawaynta kulaylka ayaa la mariyaa iyadoo la raacayo habraaca samaynta hargabka ee u dambeeyay.Iyadoo la raacayo shuruudaha habaynta ku habboon, kororka culaysyada haraaga ah ee ku lug leh ayaa awood u siinaya samaynta iyo farsamaynta labadaba ilaa heer go'an. |

| La xiray | GBK(+A) | Habka ugu dambeeya ee samaynta Qabow waxa ku xiga ka-noqoshada jawiga la xakameeyey. |

| Caadiyan | NBK(+N) | Habka ugu dambeeya ee samaynta qabowga waxaa ku xiga ka-goynta ka sarreysa barta isbeddelka sare ee jawiga kontoroolka ah. |

| Tuubooyinka Birta Saxda Sare ee Saamiyada | ||||||||||

| OD | Dhumucda (mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Xusuusin: Waxaan soo saari karnaa cabbirro kale sida shuruudahaaga.Daawaynta Dusha sare: Iftiin, Galvanized, Fosfate iwm. | ||||||||||

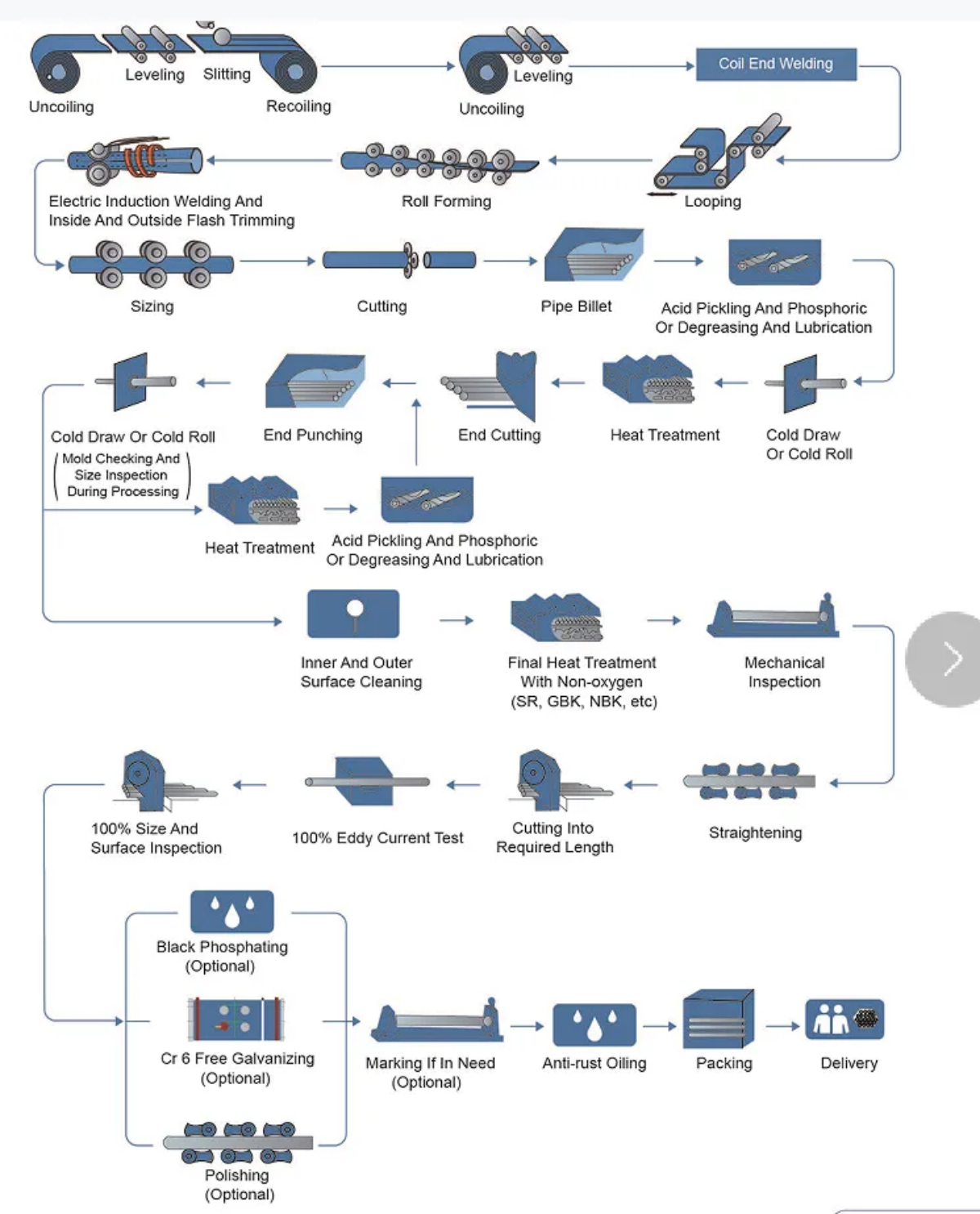

Habka wax-soo-saarka

Faa'iidooyinka

Xoojinta kormeerka alaabta ee marxalad kasta oo wax soo saarka, qalabaysan qalab tijaabo dhamaystiran: aan burbursanayn Eddy imminka, mishiinka tijaabada iska caabin cadaadis sare, mashiinka caalamiga ah ee tijaabada xajin, foorarsado flattening mishiinka baarista flares, analyzer nadaafadda, falanqeeyaha element biraha, iwm. La kulan sifooyinka farsamada ee alaabta, habka tijaabada waxqabadka, bixi dammaanad awood leh oo loogu talagalay alaabooyinka u qalma.

Hubinta tayada

1. Ku adag sida uu qabo JIS G3445 Standard ama heerar kale.

2. Muunad: Muunaduhu waa u bilaash baaritaanka.

3. Tijaabooyinka: Tijaabada buufinta milixdu / Tijaabada xajinta / Eddy hadda / tijaabinta ka kooban kiimikaad sida waafaqsan codsiga macaamiisha

4.Certificate: IATF16949, ISO9001, SGS iwm.

5.EN 10204 3.1 Shahaadada