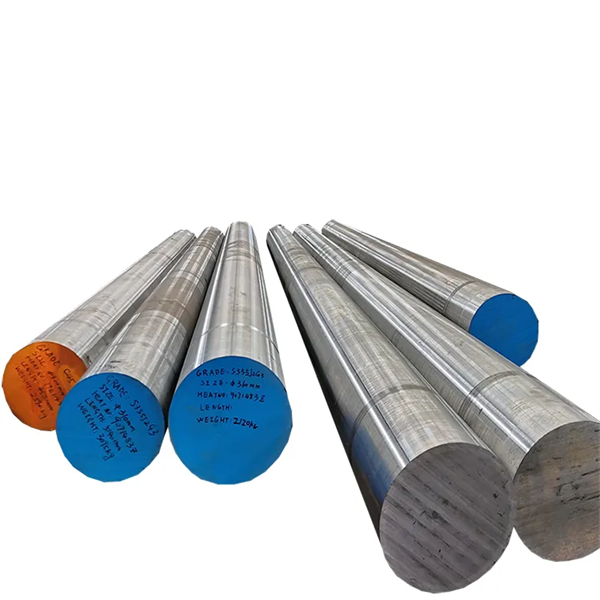

DIN 34crnimo6 bir wareeg ah 1.6582 bir bir ah

Astaamaha

34CrNiMo6 Birtu waa darajada birta birta ah ee muhiimka ah sida ku cad BS EN 10083-3: 2006.34CrNiMo6 birta waxay leedahay awood sare, adayg sare iyo karti-adkeysi wanaagsan.

34CrNiMo6 waxaa lagu dabaqaa warshadaha sida duulista, baabuurta, baabuurta, iyo difaaca qaranka.34CrNiMo6 waxay mari kartaa daawaynta kulaylka sida caadiga ah, xanaaqa, iyo deminta.Waxaa loo isticmaalaa in lagu soo saaro silsilado, boolal, geerka, gacmaha, rollers, iyo qaybo kale oo farsamo oo kala duwan.

Tilmaamid

| Cabbirka | Wareeg | Dhererka 6-1200mm |

| Saxan/Balalaan/ xannibaad | Dhumucda | |

| 6mm-500mm | ||

| Ballaca | ||

| 20mm-1000mm | ||

| Habka | EAF+LF+VD+Daawaynta Kulaylka+Forged+(ikhtiyaar) | |

| Daaweynta kulaylka | Caadiyan ;La xiray ;Demiyay ;xanaaqsan | |

| Xaaladda dusha sare | Madow;diiray;La sifayn;Mashiin;Shiidi;U soo jeestay;Milled | |

| Xaaladda gaarsiinta | Been abuur;Kulul duuban;Qabow sawiran | |

| Tijaabi | Xoog-jilicsanaanta, Xoog-soo-saarka, dhererka, aagga dhimista, qiimaha saamaynta, qallafsanaanta, cabbirka hadhuudhka, tijaabada ultrasonic, kormeerka US, tijaabada walxaha magnetic, iwm. | |

| Waqtiga dirida | 30-45 maalmood | |

| Codsiga | 34CrNiMo6 waxaa loo isticmaalaa dabada mashiinada culus, daab usheeda dhexe marawaxadaha, load sare ee qaybaha gudbinta, xidhe, usheeda dhexe, marsho, iyo sidoo kale qaybo aad u raran dhismaha motor iwm. | |

Halabuurka kiimikada (%)

| Kaarboon C | 0.3 ~ 0.38 |

| Silikoon Si | 0.4 |

| Manganese Mn | 0.5-0.8 |

| Sulfur S | ≤ 0.035 |

| Fosfooraska P | ≤ 0.025 |

| Chromium Cr | 1.3 ~ 1.7 |

| Nickel Ni | 1.3 ~ 1.7 |

| Molybdenum Mo | 0.15-0.3 |

Guryaha Makaanikada

| Xoog xajin σ b (MPa) | 850-1400 |

| Awood-soo-saarka σ s (MPa) | ≥690 ~ 1000 |

| Kordhinta δ (%) | ≥9 ~ 15% |

| Adag | 239-259 HB |

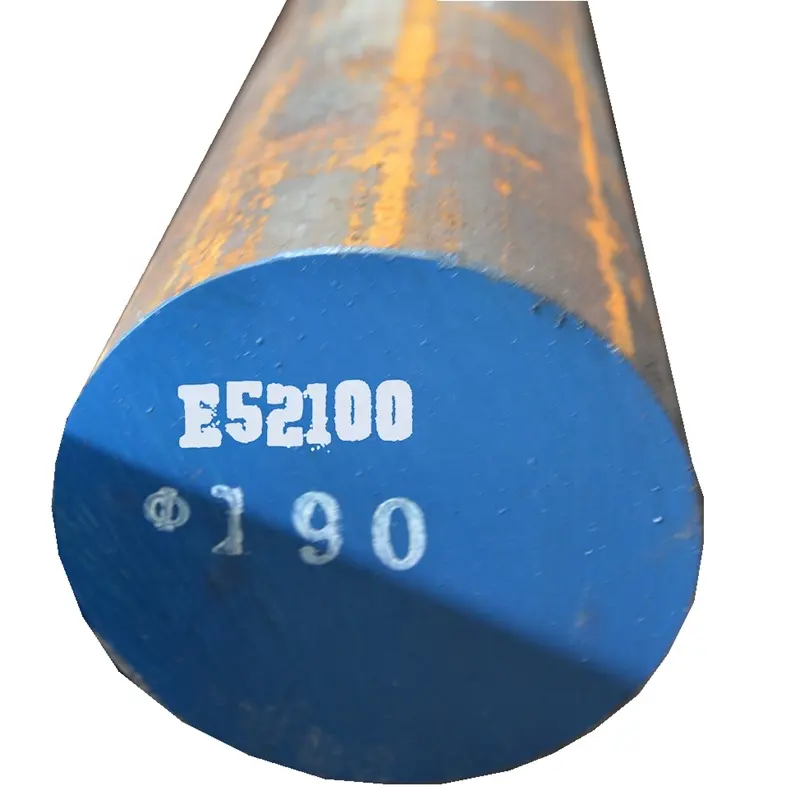

| Halbeeg kala duwan oo siman | |

| Darajo | Heerka |

| 34CrNiMo6 (1.6582) | EN 10083-3 |

| 4337 | ASTM A29 |

Xaaladda gaarsiinta

Baar foorno kulul, badiyaa xaalada dhalmada waa mid kulul oo la been abuurtay, la jeexjeexay/QT oo qallafsan oo rogan/madow madow.

Kulul duuban, sida caadiga ah xaaladda dhalmadu waa duuban kulul, la duubay/QT, oogada madow.

Dulqaad

| Dhexroorka (mm) | Dulqaad | ||

| Been abuur Wareega Bar | 80-600 | Dusha Madow:0~+5 | Rough Machined or Round:0 ~+3 |

| 650-1200 | Dusha Madow:0~+15 | Rough Machined or Round:0 ~+3 | |

| Hot Rolled Steel Round Bar | 16-310 | Dusha Madow:0~+1 | La diiray:H11 |

| Bar Wareega Birta ee Qabow Sawiran | 6-100 | Dusha Madow:H11 | La diiray:H11 |

Xidhmada

1.By xidhmooyinka, xidhmo kasta oo miisaankeedu ka yar yahay 3 tan, ee dibadda yar

dhexroor bar wareeg ah, xidhmo kasta oo leh 4 - 8 strips bir ah.

2.20 cagood weel ka kooban cabbir, dherer ka hooseeya 6000mm

3.40 cagood weel ka kooban cabbir, dherer ka hooseeya 12000mm

4.By markabka bulk, khidmadda xamuulku waa ku yar yahay xamuulka badan, iyo weyn

cabbirrada culculus laguma rari karo weelasha waxaa lagu rari karaa xamuul badan

Shahaadada Tayada: Waxaa lagu soo saaray Ingiriis, marka lagu daro shuruudaha caadiga ah, habka wax soo saarka, hantida farsamada (xoogga wax soo saarka, xoogga xajinta, dhererka iyo qallafsanaanta), saamiga been abuurka ah, natiijada tijaabada UT, Cabbirka hadhuudhka, hababka daaweynta kulaylka iyo muunadda waa lagu muujiyay Shahaadada Tayada.

Calaamadaynta: Kulaylka Lambar

Hubinta tayada

1. Ku adkee sida Shuruudaha

2. Tusaale: Muunad ayaa diyaar ah.

3. Tijaabooyinka: Tijaabada buufinta milixdu / Tijaabada xajinta / Eddy hadda / tijaabinta ka kooban kiimikaad sida waafaqsan codsiga macaamiisha

4. Shahaadada: IATF16949, ISO9001, SGS iwm.

5. EN 10204 3.1 Shahaadada